- Welcome to Lazwi Engineering 8

- info@lazwi.co.za

- +27 11 865 4422/4336/5120

Manufacturers & Supplies

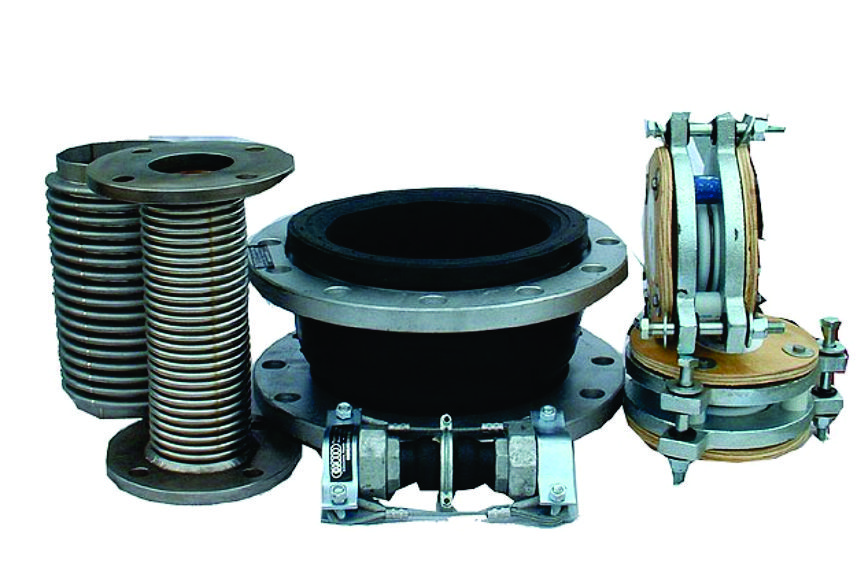

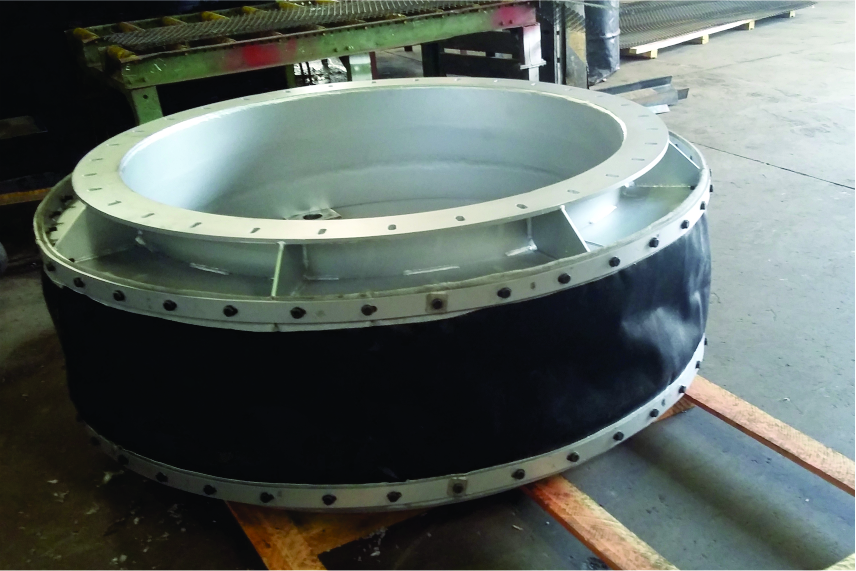

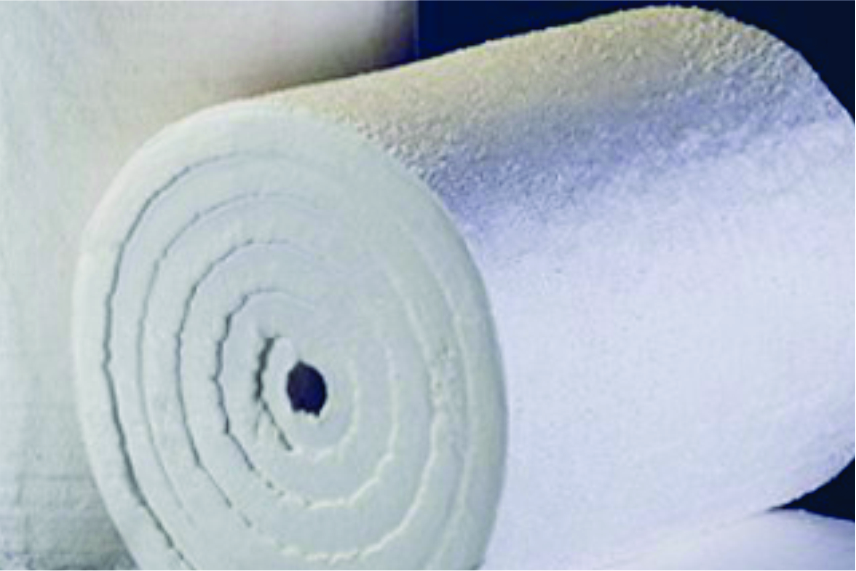

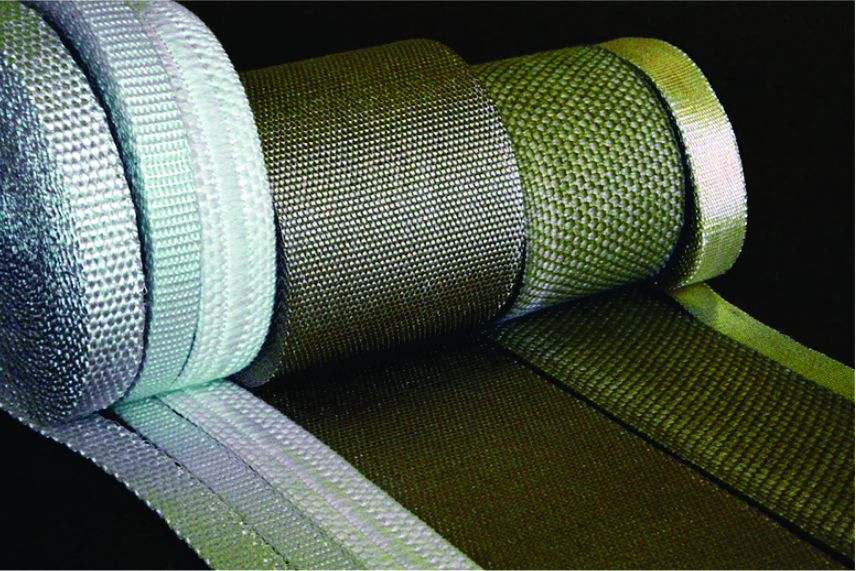

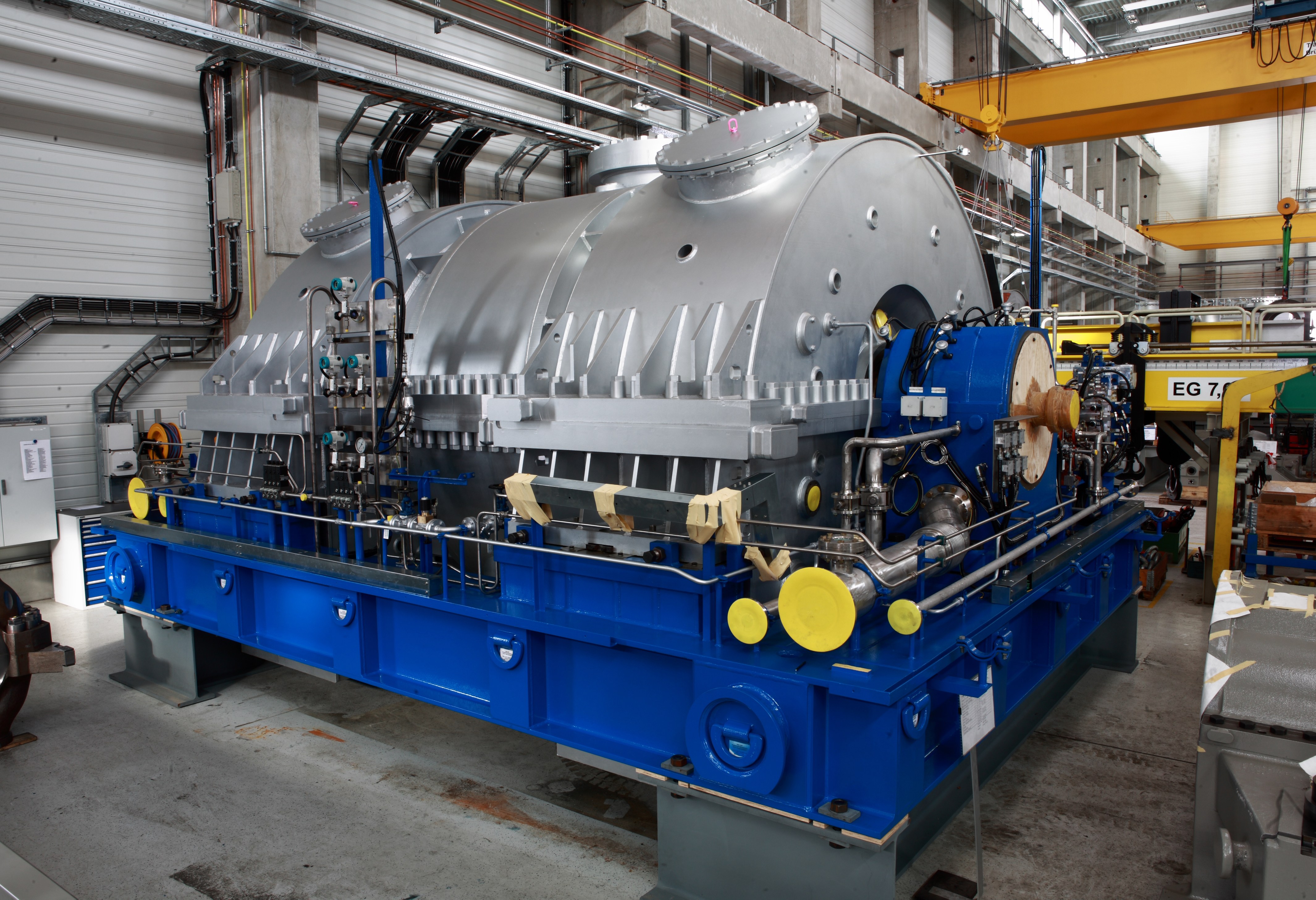

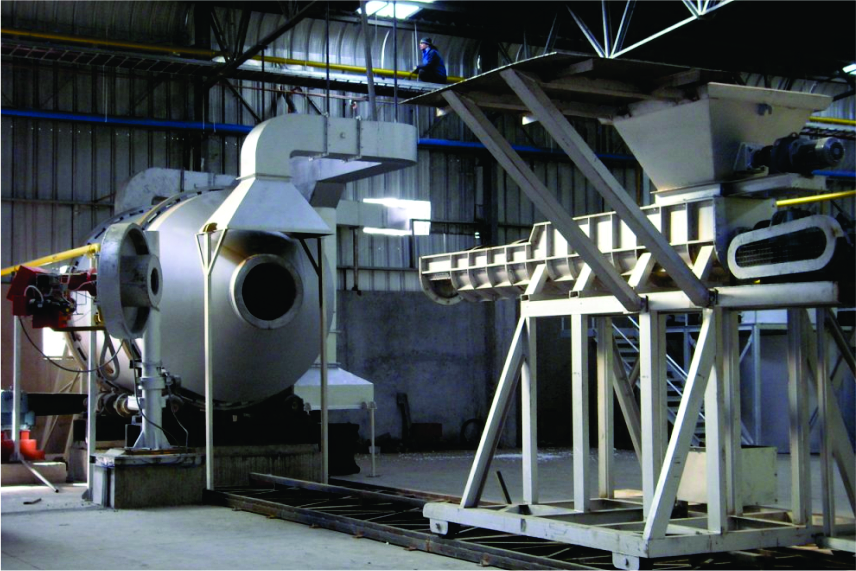

We offer Fabric Expansion Joints, Metalic Expansion Joints, Rubber Expansion Joints, Ceramic Fiber Blankets, Ceramic Fiber Ropes, Graphite and Non Graphite Seals, High Temperature Textiles Cloths, Industrail hose products and other services.